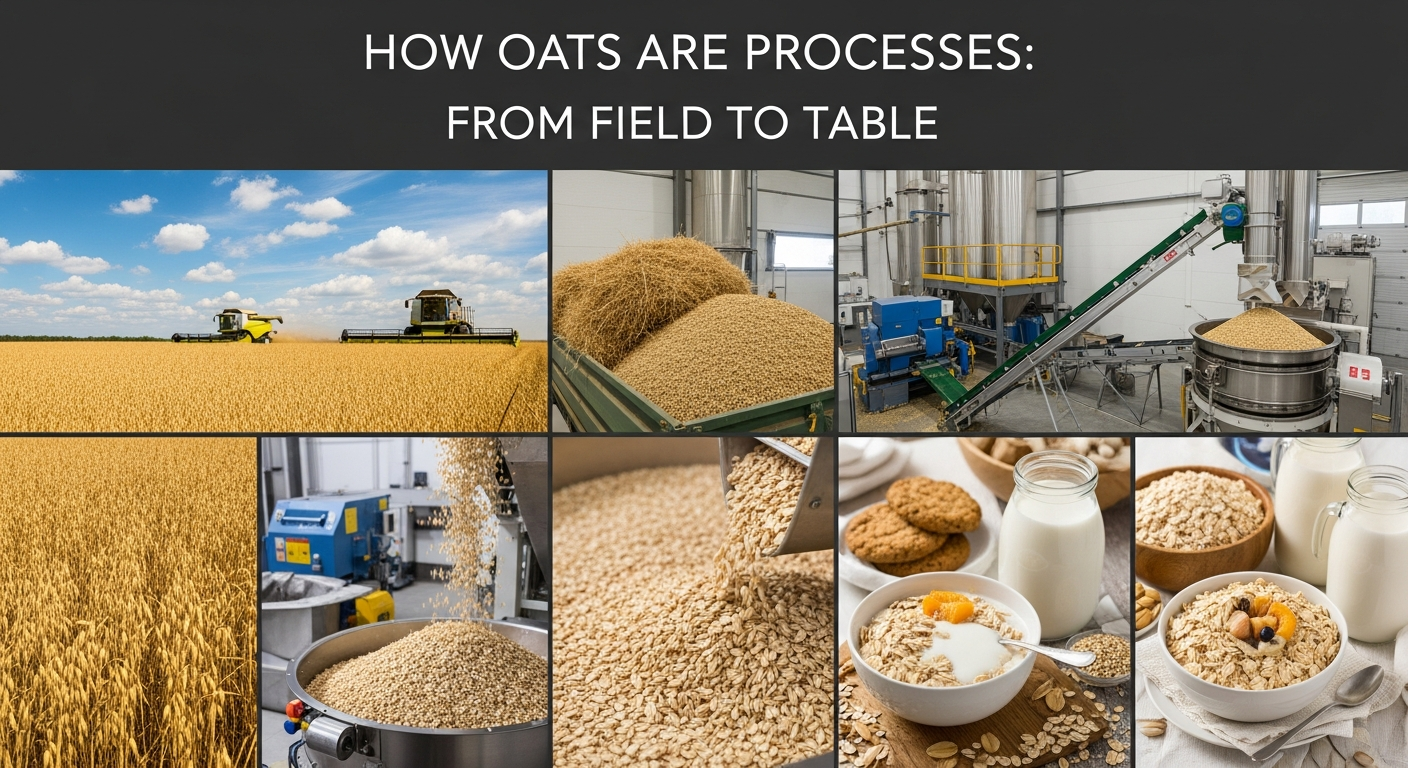

For centuries, oats have been grown as one of nature’s most wholesome whole grains due to their versatility and healthfulness. Oats continue their journey from the farm to your breakfast bowl by going through a process that helps maintain their delicious taste, unique texture, and outstanding nutritional value. Oats are full of fiber, antioxidants, vitamins, and minerals, which are beneficial for the function of your digestive system and heart and help provide you with sustained energy throughout your day. Most processing methods preserve these nutrients in oats, making them an ideal and healthy component of your balanced diet. The path that raw oat grains take includes harvesting and then cleaning, dehulling, steaming, cutting and rolling, and through each step, oats are turned into different forms such as steel cut, rolled and instant oats. Each of these forms provides specific advantages, making it possible for people to find the right oat type for their individual kitchens and lifestyles.

Understanding the Journey: An Overview of Oat Processing

The process that oats go through before getting to your kitchen is quite organized. As a result of all of the steps taken in this journey, you will have a clean, safe, nutritious grain, and one that is ready to be made into the different varieties of oats we enjoy every day. The steps of harvesting and milling are critical to ensure that the quality and natural goodness of the oats are maintained from start to finish. The majority of grains require very little processing; however, the oil in oats is extremely delicate and must be handled carefully to protect, as well as preserve, the quality of the oil, flavour and texture of oats. By learning about the processing of oats and how they are used, you will begin to better understand how unique and versatile oats are and how nutrient-dense they are as well.

How Oats Move From Farms to Milling Centers

Once oats become ready to be harvested, they will be moved from the field where they are grown to the processing plant for processing.

- Most of the time, oats are harvested in large amounts and placed onto trucks to be moved.

- Oats can be damaged by moisture so they must be transported in a way that prevents moisture entering the load.

- When the oats arrive at their destination, they will be weighed, recorded, and stored at the facility until they are cleaned.

(The movement of oats from the time they are harvested through to their arrival at their processing facility is extremely important; it allows them to remain fresh, free of contamination, and ready for the next step or steps of their processing. The proper transport methods ensure that the oats are protected during the process and are able to maintain the natural nutritional value of the oats and the natural structure of each grain.)

Key Steps That Transform Raw Oats Into Edible Grains

Oats go through a variety of processes before they become ready to eat.

Processing includes the following stages:

- Removing the inedible, tough outer shell of the oats (by dehusking).

- Steaming the oats to soften the grains and to stop them from going rancid.

- Cutting or rolling the oat groats into different types (steel-cut or rolled oats).

- Drying the oats (which allows them to remain edible for long periods of time).

(Every stage in oat processing protects the grain's natural nutrients and provides a form of oats suited to the cooking method of choice, from creamy porridge to chewy oatmeal bowls.)

Why Oat Processing Matters for Texture and Shelf Life

Oats have a wide variety of textures due to the way they are processed (smooth, rolled, thick, chewy, etc.).

- The steaming of oats causes the oat oil to remain stable, preventing spoilage.

- Cutting and rolling the oats results in different degrees of softness and will affect how long they take to cook or how soft they will be after cooking.

- Properly dried oats will last longer than improperly dried oats.

Good processing of oats enables the oats to retain their whole grain benefits, while also making it easier to store, prepare, and enjoy the many uses for oats in recipes.

The Harvest: Gathering and Sorting Raw Oats

Before the oats can be processed, they need to have been harvested at the optimal time. In addition, cleaning and sorting of the harvested oats is vital to determine what the final quality of the product will be. Farmers monitor the ripeness, moisture content, and weather at the time of harvest so the oats can be picked at their highest nutritional value. After harvesting, the oats will undergo thorough cleaning to remove impurities and debris, along with sorting into different grades based on quality for milling.

How Oats Are Harvested at Peak Ripeness

- Growers obtain and prepare oat crops during mature growth.

- Oat Farmers utilize Machines for collecting and cutting oat stalks.

- Moisture tests are performed to validate that the oat grains were Un-Harvested prematurely or too late; both decrease vapidness of the oat and increase quality.

(Optimal harvest times help preserve oat's natural fresh, crunchy kernel texture and Whole Grain Properties of the grain.)

Cleaning Oats to Remove Stones, Dust & Impurities

Once harvested, oats need to be cleaned multiple times prior to processing. Cleaning typically

occurs through three methods:

- 1) Air blowers are used to remove light contaminants, such as dust and husk pieces.

- 2) Sieving equipment filters out stones and heavier contaminants.

- 3) A magnetic system catches any unwanted metal contaminants.

(It is critical to completely clean the oats. Cleaning is necessary so that processing is done in a manner that maintains the safety, hygienic nature and nutrition of oats through to the next processing step).

Grading Oats for Size, Color & Quality

Once oats have been cleaned, they are sorted into groups according to their quality.

- Larger, uniform-appearance oats will be used to create premium oat products.

- Smaller and/or broken oats may be used for oat flour and bran use.

- Color grading maintains consistent quality and freshness.

(Through grading, manufacturers ensure that every batch of oats produced is attractive, cooks evenly and has high emotional and physical attributes.)

Understanding the Journey: An Overview of Oat Processing

The journey of oats before they arrive in your kitchen is well-monitored from the moment the grains are harvested, cleaned, dehusked, cut, and rolled to the final step; as all steps will help to maintain the freshness level and high nutritional value of oats. While most consumers are unaware of the processing that oats go through prior to being harvested, the goal of processing is to be as gentle as possible while maintaining a whole grain form. Throughout the processing of the oat, the oat retains its natural fibre, vitamins, minerals, and antioxidants, making them an excellent option for healthy eating. Whether consumed as steel-cut oats, rolled oats, or instant oats, all forms begin with the same nutrient-dense raw oat groat.

How Oats Move From Farms to Milling Centers

After oats have been harvested, they will be shipped from farms to a specific milling centre for processing. Modern milling centres have sophisticated sorting, cleaning, and dehusking equipment that allows them to handle large volumes of oats efficiently.

The key functions of transporting oats to milling centres are to:

- Keep the oats free from moisture so they do not spoil

- Keep the oats in good condition and fresh

- Keep the oats in a safe and clean environment

- Keep the oats in their natural whole-grain state.

The above processes ensure the oats will be received by mill operators in a clean and stable form, so that they can be modified into food products.

Key Steps That Transform Raw Oats Into Edible Grains

Upon arrival at the mill, oats will go through various processing steps that impact the final product. People typically think that processed when they see oats, but every step is gentle in comparison to processed grains

The major steps in oat processing include:

- the removal of the untrue hard outer hull or husk

- the heat treatment of the oats to maintain the healthy oil content

- the cutting and/or rolling of the groat to produce steel cut, rolled and/or instant oats

- the flaking of the steamed groat for easy handling

- the cooling and drying of the oats for long-term storage

All of the above steps occur so that oats maintain a clean, safe, stable shelf-life, while maintaining most of their nutrition.

Why Oat Processing Matters for Texture and Shelf Life

Properly processing oats ensures that they maintain their wholesome flavour while also extending their shelf-life. Kilning and steaming prevent the oil in oats from becoming rancid, while cutting and/or rolling affect the cooking duration and texture.

Properly processing oats also has the following advantages:

- Enhances the natural flavour and aroma of oats

- Prevents oils in oats from becoming rancid

- Creates consistency in cooking results

- Increases versatility of oats as ingredient

As a result of proper processing, oats are one of only very few grains that have kept their healthful properties through processing.

The Harvest: Gathering and Sorting Raw Oats

Oats begin their journey in the fields situated in cooler climate zones and will eventually be harvested when they have reached full maturity. In order to understand why oats that have not been processed and oats that have been minimally processed are different, we must first recognize that whole oat groats are created during harvest. After harvesting, raw oats are thoroughly cleaned and sorted, to ensure that only those grains that are of the highest quality continue through the milling process.It is at this stage in the oat harvesting cycle when we can maintain purity, safety and nutrient retention of all oat products powered by the oat.

How Oats Are Harvested at Peak Ripeness

Oats are harvested at the time they have taken on the light golden colour and hardness of the grain has firmed enough so that they are able to separate from the stalk. To harvest, a farmer uses a combine that has been specially designed to efficiently cut, thresh and collect the grains. Timing of the harvest is critical; an early harvest will result in soft grains, while a late harvest will result in an increased risk of spoilage.

To successfully harvest:

- Maintain the shape and nutrient density of the grain

- Minimize the risk of mildew or moisture damage to the grain

- Provides a stable and uniform grain for the milling process.

The proper harvest of oats ensures that the highest quality of whole oat groat—the least processed and most natural type of the oat—will be available.

Cleaning Oats to Remove Stones, Dust & Impurities

Oats have natural impurities being harvested, like straw pieces and stones, so cleaning machines remove them with air blowing devices, grates, magnets and sieves.

Cleaning protects:

- the safety and purity of oats;

- they help avoid cross contamination when being milled;

- They maintain consistency and improve quality.

Clean oats produce cleaner and healthier final products.

Grading Oats for Size, Color & Quality

The grading process involves grading clean oats according to size, color, texture, and density. Only the highest grade of oats are sent to be de-husked and ground into flour; lower grades are separated for animal feed, thus reducing waste.

Grading protects:

- that only the highest quality oats end up in the hands of consumers;

- allow for consistent cooking;

- provide the greatest nutritional value of the finished oatmeal.

The grading process shows how extensively sorted oats go through before being packaged as oatmeal in supermarkets.

Diverse Products: Final Forms of Processed Oats in Stores

The way oats are processed impacts the shape or form of the oat product including the Texture, Cooking Time and Flavor of the Oats. Knowing all of the options that you have regarding these different types will allow you to choose the right type of oats for your meal preparation whether you want a delicious breakfast, a quick energy snack or an ingredient for cooking. While the processes for all oat types differ, they all offer many nutritional benefits and provide the whole grain oat product experience.

Steel-Cut, Rolled & Instant Oats—What’s the Difference?

Steel cut oats are the least processed type of oats...they are basically just cut into chunks of oat groats which means they have the most firmness and chewiness of all oat types. Rolled oats have been steamed and pressed so they are softer and will cook much quicker than steel cut oats. Instant oats have been steamed and pressed even more than rolled oats which results in them cooking the fastest.

Highlights:

- Steel Cut Oats: Very little processing; very firm texture; long cooking time.

- Rolled Oats: Some processing; moderately soft texture; moderate cooking time.

- Instant Oats: Most processing; fastest cooking; perfect for busy mornings!

So which oats should you eat?

If you are asking what are the healthiest oats, the correct answer is Steel Cut Oats. They are the least processed type of oats and, therefore, retain the most of the structural characteristics of the grain.

Oat Flour, Oat Bran & Groats for Versatile Cooking

Even though most people associate oats with the traditional way to eat oats (i.e., cooked as oatmeal), oats can be processed into a number of different oat-based products for use in cooking. Oat flour is the finely ground form of oats that can be used to bake all types of baked goods (such as bread) as well as used to thicken sauces and gravies. The outer husk of the oat (the groat) is called oat bran, and it contains a significant amount of soluble fiber. The whole oat groats contain the maximum amount of nutrients and have the heartiest texture.

Some Uses for These Oat Products Include:

- Oat flour: Breads, muffins, pancakes, and cookies

- Oat bran: Smoothies, porridge (or oatmeal), and fibre-rich foods

- Oat groats: Soups, salads, pilafs, and whole grain dishes (like oats and pasta)

Because of the many varieties of oats available, they can be used in a variety of ways for different cooking needs.

Uses of Each Oat Type for Everyday Meals

Oats are extremely versatile, and can be added to meals at any time of day. Steel-cut oats work well for both warm breakfasts and savoury breakfasts, or porridge, while rolled oats are excellent for using in smoothies, energy balls, and homemade granola bars. Instant oats can be prepared in less than five minutes to provide you with a healthy breakfast option right away.

Some Examples of How Oats Are Commonly Used for These Three Meals:

- Oatmeal: Hot bowls or warm savoury oat bowls (i.e., oatmeal porridge or savoury oatmeal)

- Snacks: Energy balls, granola bars and baked oatmeal

- Meals: Savoury oat khichdi (Indian-style soup) or savoury oats and vegetable soup

Sustainability and Modern Innovations in Oat Processing

Not only are oats highly nutritious as a grain, but they are also among the most environmentally sustainable in the world to cultivate and process. Today, environmentally responsible oat farming focuses on conserving natural resources and reducing carbon emissions whilst maximizing the efficiency of the milling process. As we develop more advanced agricultural technologies and methods, oats will become an even more environmentally sustainable source of nutrition on a global scale.

Eco-Friendly Farming Practices for Better Oats

By utilizing crop rotation, minimal use of pesticides and soil-building techniques, farmers produce high-quality oats that are better for the environment. In many cases, farmers who grow oats utilize a minimal amount of water compared to other grains. Therefore, oats can be viewed as environmentally responsible crops.

Examples of Environmentally Responsible Practices

- Use of minimal water

- Soil Building Crop Rotation

- Using Natural Pest Control

- Lowering Chemical Dependency

By implementing these environmentally responsible practices, farmers are providing consumers with improved-quality grains while also protecting the environment.

Energy-Efficient Milling & Waste Reduction

Today, oat mills are committed to increasing their sustainability, and therefore, the industry provides, through the use of energy-efficient equipment, and recycling of oat hulls into animal feed (or) biomass as fuel, a decrease in waste and carbon emissions. This means that the entire oat plant can be used for a meaningful purpose.

Benefits of Sustainable Milling:

- Decreased energy requirements

- Reuse of oat hulls to eliminate waste

- Reduced emissions through improved kilns

- Cleaner processing environments

Using sustainable milling methods will allow for the responsible and efficient use of the resources associated with processing oats.

Technological Advancements in Grain Processing

The next generation of technology has improved grain processing for oats by improving grain quality, food safety, and nutrient preservation. Advancements in cleaning technology remove unwanted contaminants and the use of a variety of cutting and rolling machines enables an even texture across all oat grain; also, advanced technology uses steam to stabilize the grain and allows the oats to be packaged in a manner that provides the longest shelf life possible.

Improvements in Modern Technology:

- Advanced sorting for grain purity

- Precision rolling for an even flake size

- Steam stabilization to maintain nutrient content

- Automated packaging for an extended shelf life

Innovation has led to a safer, fresher, and healthier oat product.

FAQs

Q1. How oats are processed from harvest to packaging ?

Oats are harvested, cleaned, dehusked into groats, then cut or rolled, steamed if needed, and finally packaged for freshness and safety.

Q2. What oats are not processed ?

Whole oat groats are the least processed form, retaining their full grain structure with minimal mechanical handling.

Q3. Are steel-cut oats more natural than rolled oats ?

Yes—steel-cut oats are simply chopped groats, while rolled oats undergo steaming and flattening for faster cooking.

Q4. Do processing steps reduce the nutrition in oats ?

No, oats remain whole grains through most processing methods; their fiber, vitamins, and minerals stay largely intact.

Q5. Which type of oats is the healthiest ?

Steel-cut oats and whole oat groats are considered the healthiest because they are the least processed and most nutrient-dense.

Conclusion: Why Understanding How Oats Are Processed Matters for Health-Conscious Consumers

The knowledge of how oats are processed empowers connoisseurs to choose the most appropriate oats based on their lifestyle choices—.eg., if they need less processing and more convenience. Each style will provide positive attributes of being whole-grain; however, knowing the processing methods along with the nutritional quality allows for customized, healthier meal preparation, providing the body with better digestion, energy balance and more nutrients.

Through learning and understanding what oats have not been processed and how nutrient preservation occurs during the modern milling process, you can confidently and intelligently select the type of oats you will eat. Choosing the type of oats with thoughts of sustainability, quality and overall health is empowering when establishing your wellness plan.